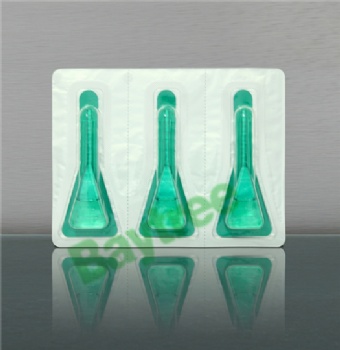

PVC,PET/EVOH/PE high barrier film

It is manufactured via multi-layer co-extrusion or dry lamination processes, widely suitable for pharmaceutical, food, cosmetic and health products packaging needs, and complies with pharmaceutical standards such as YBB and ISO 15378.

Its core advantage lies in "triple performance synergy": the outer PVC layer ensures material stiffness and impact resistance, meeting the forming and transportation protection requirements of automated packaging equipment; the middle EVOH layer is a high-efficiency barrier layer, with much better barrier properties against oxygen and carbon dioxide than traditional materials, which can effectively delay the oxidation and deterioration of contents (such as oxidizable drugs and health foods);

The inner PE layer has excellent chemical resistance and heat-sealability, which not only prevents component migration between the packaging and contents but also enables fast and tight heat-sealing to avoid leakage. In addition, the material can be customized into transparent or light-shielding specifications on demand, balancing safety, barrier property, and practicality, making it a preferred choice for high-demand packaging scenarios.