Cold Alu-Alu forming foil

Its core advantages lie in "safe protection + strong adaptability": the pure aluminum foil substrate can effectively block oxygen, water vapor and ultraviolet rays, preventing drug oxidation, moisture absorption or photosensitive degradation (e.g., antibiotics, vitamins); the pharmaceutical-grade coating (such as acrylic resin) on the surface ensures no migration of harmful components during sealing, ensuring drug safety; the cold-press process requires no high temperature, making it especially suitable for packaging heat-sensitive drugs and preventing high temperature from damaging drug efficacy.

In addition, cold aluminum can be printed with drug batch numbers, expiration dates and other information on demand, and has good tearability for easy access by patients, making it a key pharmaceutical packaging material that balances protection, safety and practicality.

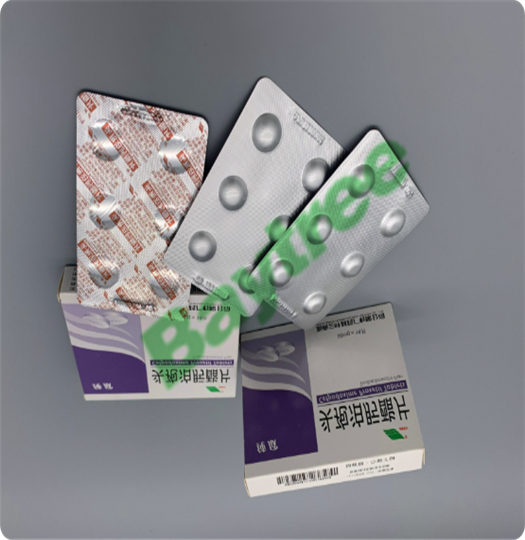

Cold forming aluminum foil is one of the most high-barrier material among primary packing materials.Due the different sizes and shapes of medicines, alu alu foil with different specification will cater to customized need.

Compared with other high barrier effect products like PVDC, cold forming alu alu foil has better cost-effecient benefit. The shining and glossy surface also makes the product packing look fancy and high-end.