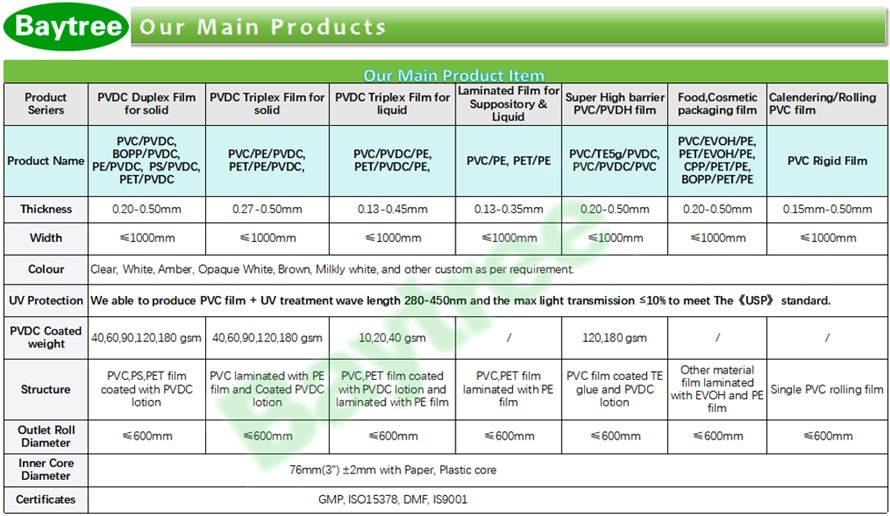

PVC/PE for suppository

The product strictly complies with pharmaceutical packaging standards (such as YBB, ISO 15378) and combines the advantages of the two materials: the PVC layer ensures excellent stiffness and formability, which can accurately adapt to the special shapes of suppositories (such as bullet shape, torpedo shape) and ensure tight fit between the packaging and the drug; the PE layer enhances material toughness and sealing performance, preventing suppositories from being damaged by extrusion during storage and transportation, while reducing the invasion of external moisture and impurities to maintain the stability of suppository efficacy.

In addition, the material meets pharmaceutical hygiene standards (no migration of harmful impurities, no pathogenic bacteria) and can be customized into transparent or light-shielding specifications on demand to adapt to suppository drugs with different stability requirements, making it a preferred suppository packaging material that balances practicality, safety and compliance.