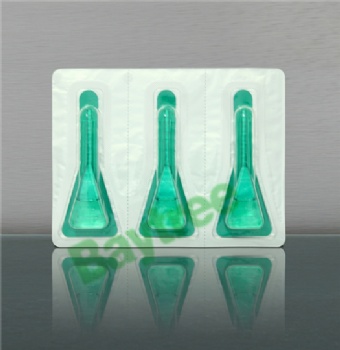

PVC/PE film for liquid

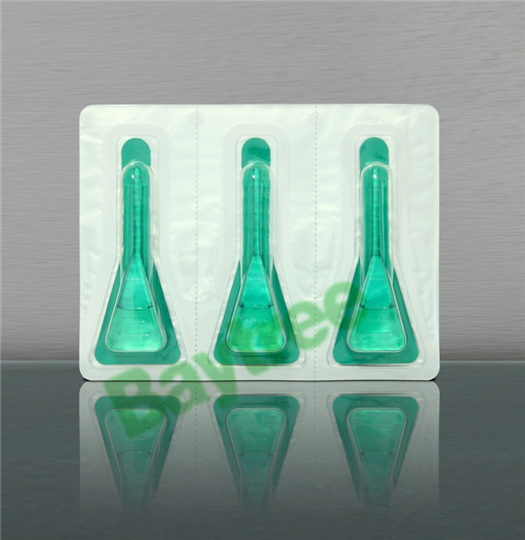

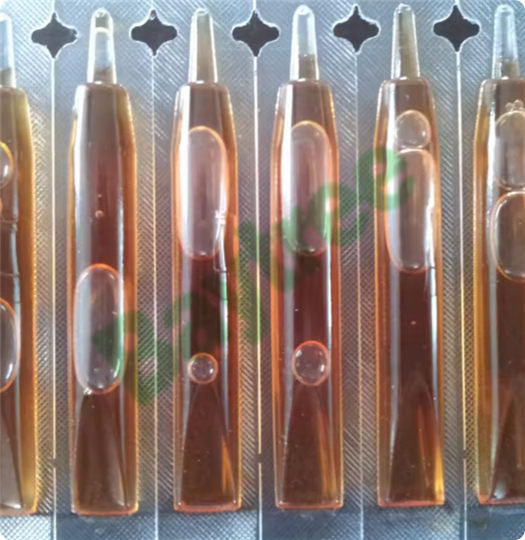

Its core advantages lie in "double protection + adaptability": the PVC layer ensures material stiffness and forming stability, which can accurately form independent liquid drug trays (such as single-dose packaging trays for oral liquids and drops) to prevent liquid leakage caused by tray deformation; the PE layer has excellent sealing and chemical resistance, which can isolate external moisture and impurities, while preventing component migration between liquid drugs and packaging to ensure the purity and efficacy of the liquid medicine.

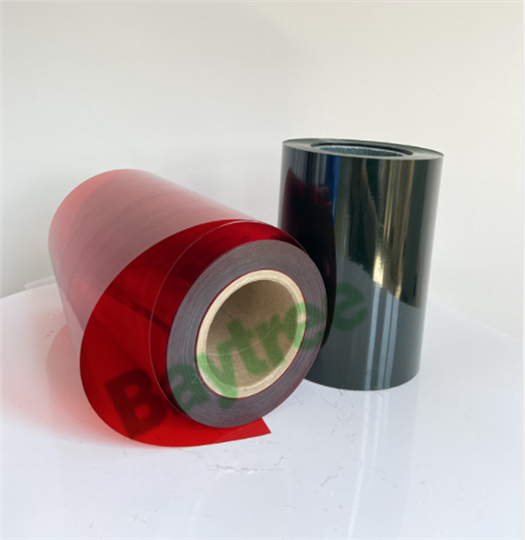

In addition, the material can be customized into transparent or light-shielding specifications on demand to adapt to liquid drugs with different light-proof requirements (such as vitamin drops and traditional Chinese medicine oral liquids), making it a preferred liquid pharmaceutical packaging material that balances safety, sealing and formability.