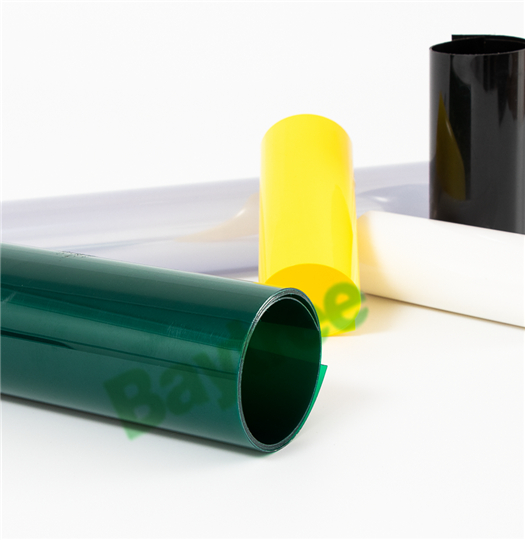

PVC/PVDC/PE film

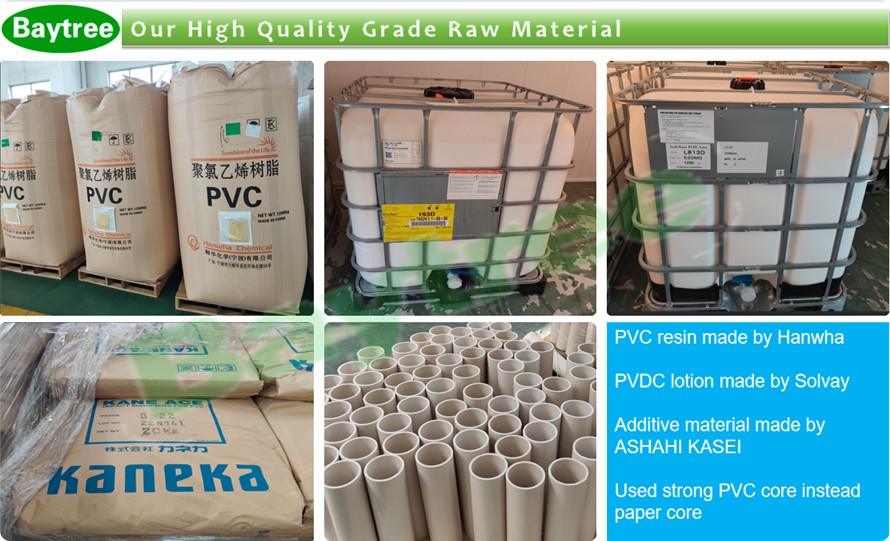

The product strictly complies with pharmaceutical packaging standards such as YBB and ISO 15378, integrating the advantages of three layers: the bottom PVC layer ensures excellent thermoformability, which can adapt to high-speed packaging equipment to meet the automated packaging needs of solid preparations like capsules and tablets; the middle PVDC layer provides high barrier properties, which can effectively block oxygen, water vapor and light, delay drug oxidation, moisture absorption or degradation, and extend the shelf life; the surface PE layer enhances material toughness and impact resistance, preventing packaging damage during transportation and storage, while improving the touch and safety during use.

In addition, the material meets pharmaceutical hygiene standards (no migration of harmful impurities, no pathogenic bacteria) and can be added with UV protection coating on demand for packaging photosensitive drugs, making it a preferred pharmaceutical packaging material that balances compliance, protection and practicality.